We're reaching the home stretch of the mechanical part of the build. The end is in sight but there's still a lot of seemingly little things left that take up a lot of time left to do. First up since the last update, I ended up coming across my dream wheels that so rarely show up for sale let alone brand new I had no choice but to jump on them. They're Mugen MF10s in 17x9 +42 offset in the trademark dark bronze color. At only around 15lbs per wheel they're very light and at the perfect offset to clear the Spoon calipers (and probably any big brake kit in the market) without any spacers.

|

| Mugen 17x9 +42 MF10 wrapped in Bridgestone RE-71R - 3/3/2018 |

|

| The only wheel box I'll probably ever keep - 3/3/2018 |

The proper graded bolts for the seat rails arrived so both driver and passenger side modified OEM rails are now complete. We verified fitment and it's perfect but the seats are staying out of the car until after the body work is complete. There's a bit of a challenge getting the OEM seat belt working in this configuration because I also have eyebolts that go to the transmission tunnel for the 6pt harnesses that interfere with the seat operation if the harness is placed in the stock location. We opted to instead mount the seatbelt receiver on the eyebolt rather than the rail. This simplified the setup, ensured proper operation of both the OEM 3-pt seat belt and 6-pt harnesses, and preserved the full range of adjustment in seat position.

|

| Completed modified OEM seat rails with Recaro Pole Position - 3/3/2018 |

The connector for the OEM map sensor had a broken clip so I ordered a new MAP sensor pigtail but rather than soldering it in place,

SJF simply repinned the new connector and we also put in the OEM part that zip ties the connector to the MAP sensor. It's crazy that this part even exists but under high RPMs, there's a known issue where the connector loosens enough to cause issues. Specifically the TSB mentions intermittent hesitation during hard acceleration. The OEM part number is 32125-PCX-003 and is simply a plastic clip that goes over the MAP sensor with an integrated zip tie to hold everything place.

|

| New MAP sensor connector - 3/3/2018 |

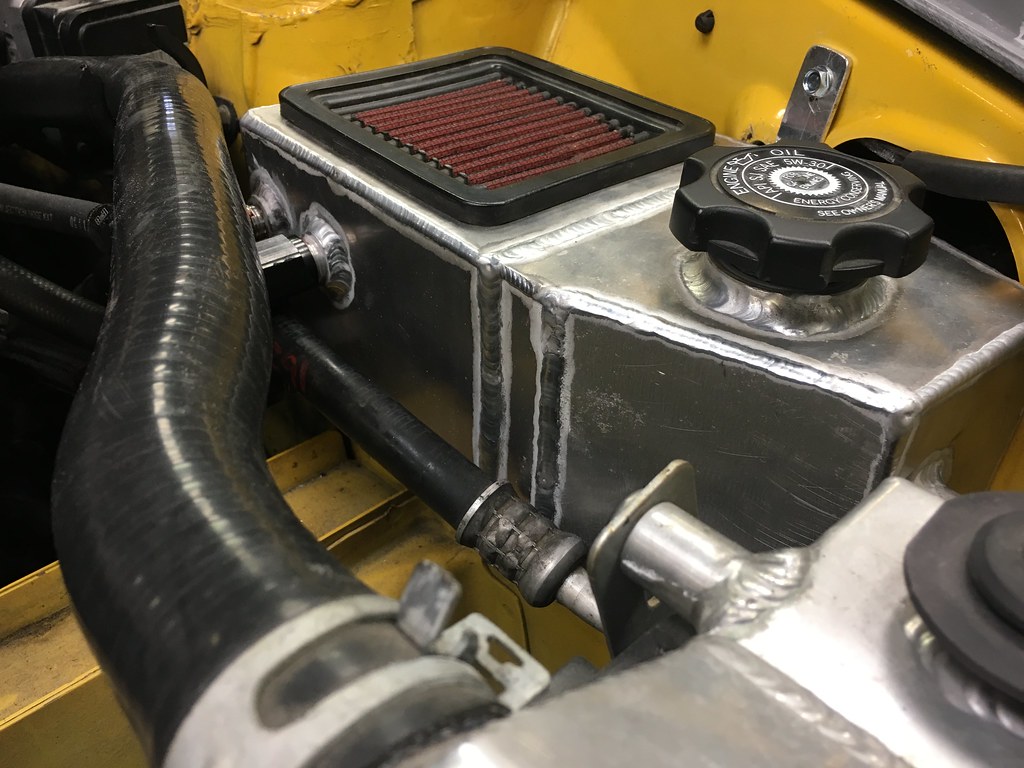

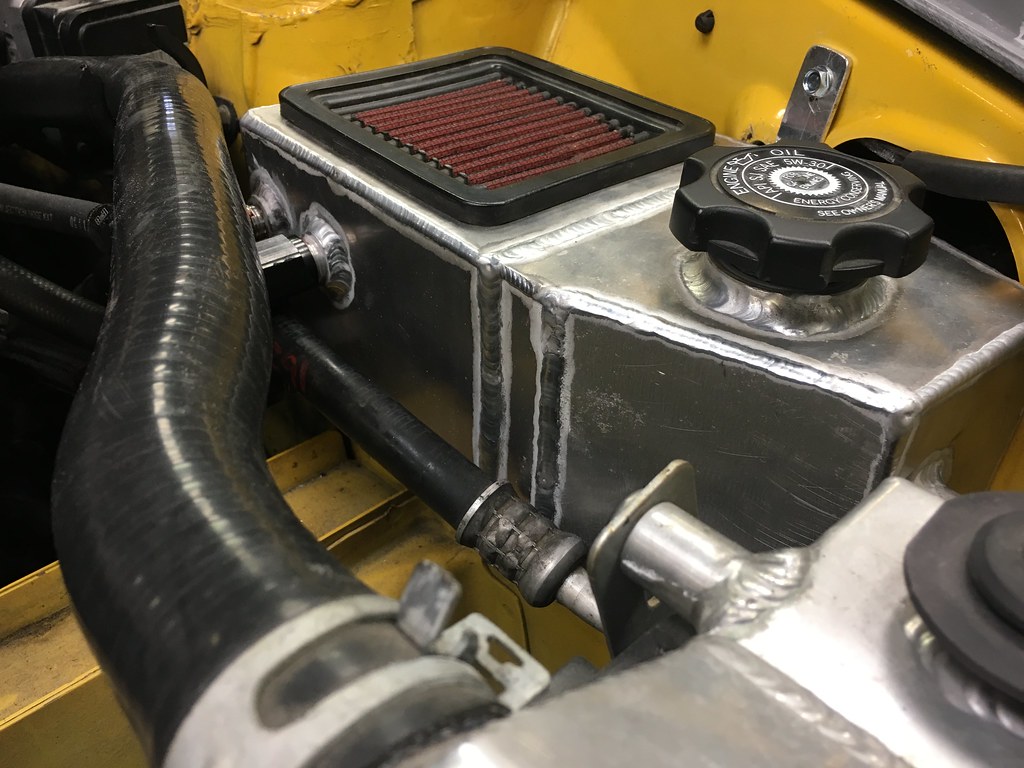

Evans Tuning had built me a custom radiator overflow / oil catch can combo for my BSP build years ago but it wouldn't work as is anymore because it left no gap for the AC hose going from the condenser to the compressor to go through. The overflow had to get trimmed and re-welded by SJF's friend Del. One of the bungs was cross threaded and a new bung needed to be welded in and while we were at it, some additional brackets were added to properly secure it to the chassis.

|

| Custom Radiator overflow modified to fit AC hose - 3/1/2018 |

Continuing on with the AC, we finally got all the right hard lines and everything in now installed. I opted to get a new condenser and drier rather than use the used one I previously got since I couldn't ensure that no contaminants had gotten into the system. Obviously with the AC previously uninstalled I'd need a new longer serperntine belt. I went with the Continental Elite 4060578 Poly-V / Serpentine Belt rather than OEM. It's a bit cheaper than OEM and proven to be just as good.

|

| New AC condenser and drier - 3/4/2018 |

|

| Main AC hard lines reinstalled - 3/4/2018 |

|

| AC compressor and new serpentine belt - 3/4/2018 |

|

| New Continental Elite serpentine belt - 3/4/2018 |

With the AC finally in, the K&N FIPK intake could finally be installed. We were a bit worried we would be able to clear the AC lines and oil cooler hoses but there's just enough room under the heat shield to squeeze it through.

|

| K&N FIPK installed - 3/4/2018 |

|

| Oil cooler lines routed under the K&N heat shield - 3/4/2018 |

Other small things that got taken care of included SJF fabricating appropriate rear bumper lower brackets. AP2 rear bumpers sit lower than AP1 rear bumpers so we needed longer brackets to secure the lower portion.

|

| Rear bumper brackets - 3/1/2018 |

I picked up eight aluminum 1.5" bore clamps to secure the shoulder harnesses from sliding out of position. This is particularly important for proper safety as you don't want the harnesses moving left or right once you strap in.

|

| Aluminum 1.5" clamping collars - 3/3/2018 |

|

| Harnesses secured and excess webbing rolled up - 3/3/2018 |

The USB charging outlets we installed at the back of the glove box last week had to be relocated. With the hard top and tonneau cover on it's a bit difficult to access it so we relocated it to the top of the secret compartment instead. The

Modifry glove box organizing was also finally back in stock so I can keep things organized.

|

| USB charging outlets relocated - 3/3/2018 |

|

| Modifry glove box organizer - 3/3/2018 |

SJF also noticed a bit of weeping from the outer bleed screw on the Spoon calipers. After backing it out and retorquing it to 7Nm, we re-bled the brakes and so far the brakes feel good again. The car is scheduled to go back on the dyno at Evans Tuning in 2 weeks to be retuned weather permitting so it's crunch time and the final bits and pieces need to get sorted so we can make sure everything is working as expected before I go there.

No comments:

Post a Comment